How can we help?

A heritage of precision engineering

Instro can trace our historical roots back to 1964 when it started operations for the UK MoD as a precision engineering contract manufacturer. Today, that heritage of precision engineering and rugged design is at the core of our products which are fielded in more than 50 countries.

Instro manufacture and supply an extensive range of cutting-edge precision technology directly to end users, OEMs as part of a larger system and offer a comprehensive capability as a prime supplier.

1960

The Company was founded by David Parsons in his garage in Tunbridge Wells and traded under Phyall Products Limited

1964

Incorporated as Instro Precision Limited

1970

Tallboy Tripod was into major contracts

1976

Instro’s first Optical Viking

was invented

1987

Company moved to Broadstairs

1991

Optical Norseman designed

1992

The First Motorised Pan & Tilt Heads were developed

1999

The Viking 2000 sold and is one of our top sellers to this day

2001

The Mini Pan & Tilt Fine Adjust was designed and became a best seller

2006

The first prototype of the Remote Observation System (ROS) was designed

2019

Move to the New Site

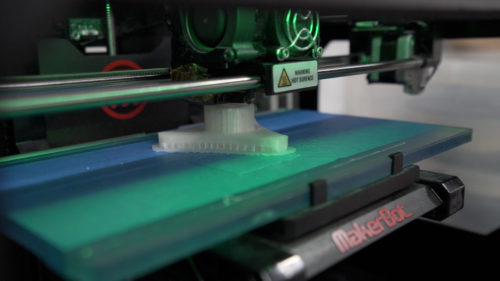

Bespoke Engineering

Instro has been a market leader in designing bespoke systems for over half a century

Manufacturing Capabilities

Brand new state-of-the-art 270002ft Centre of Excellence for manufacturing in the UK

Class 8 Clean Room

Brand new, highly advanced, purpose-built Class 8 Clean room, to continue Instro's constant pursuit of excellence

In-house design & manufacturing capabilities

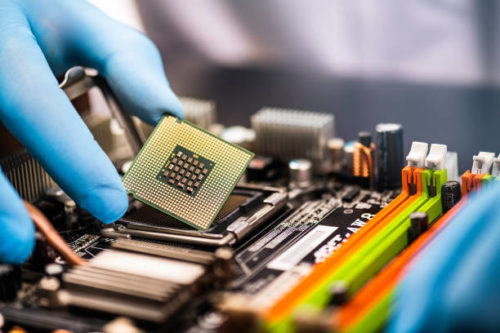

Instro engineering capabilities encompass the key disciplines we need to support and drive Instro’s continuing growth.

Core to Instro’s engineering capabilities are a deep understanding of accurate angle measurement technologies and methods that are fundamental to our digital goniometer and motorised head product lines.

Our team has many years proven experience of:

- analogue and digital circuit design using microprocessors and FPGAs as appropriate;

- embedded and application software development including digital video and digital map display;

- solar, celestial, magnetic and earth rate north-finding technologies and associated geographic calculations;

- precision mechanical design delivering ruggedness, all weather capabilities as well as minimum SWAP (size, weight and power);

- servo systems for precise control of sensor line of sight; and

- systems engineering and integration to deliver complete solutions for our customers.

Customer and R&D projects are managed by project managers who are able to draw upon the company’s whole range of skills to deliver high performance yet cost effective solutions for our customers.

Instro’s production capabilities enable us to meet our commitments through a combination of in house manufacture, assembly and strategic partnering within our supply chain. Our core products require intricate skills & design ensuring a quality product every time. Our approach to Continuous Improvement means that we don’t just settle for the status quo but we challenge the norm and are always striving to improve.

Our 3100m2 state of the art facility based in Sandwich, Kent includes 2200m2 of manufacturing and test area. With capabilities that include;

- Class 7 Cleanroom Optics Assembly facility

- Class 8 Cleanroom Camera Maintenance facility

- Prototype & rapid manufacturing cell

- CNC Miling & Tuning

- Environmental Stress screening facility

- Thermal Chambers

- Electrodynamic Vibration Shaker

- 6 Axis Hexapod

And much more, allowing optimal onsite customer support.

Instro is the market leader in north-finding technologies, precision manufacturing and our core product line, expertise we have developed over many years by design focused attention and listening to the voice of our customers’ requirements. Meeting the needs for rugged, reliable and dependable products providing professional through life support.

Quality is at the core of our business strategy which is portrayed in our ability to design and control our machined parts to tight tolerances with the latest measuring equipment and facilities.

Our Quality integrated management system conforms to the internationally recognised ISO9001:2015 and ISO14001:2015 standards which are subject to regular audit assessment by an accredited independent assessor.

We recognise the systems and capabilities we produce are used in some of the most demanding and hostile environments in the world. To meet the expectations of our customers before our products leave the factory they are put through an intensive quality inspection process which ensures the highest standards are met and maintained, giving our customers the best possible experience.